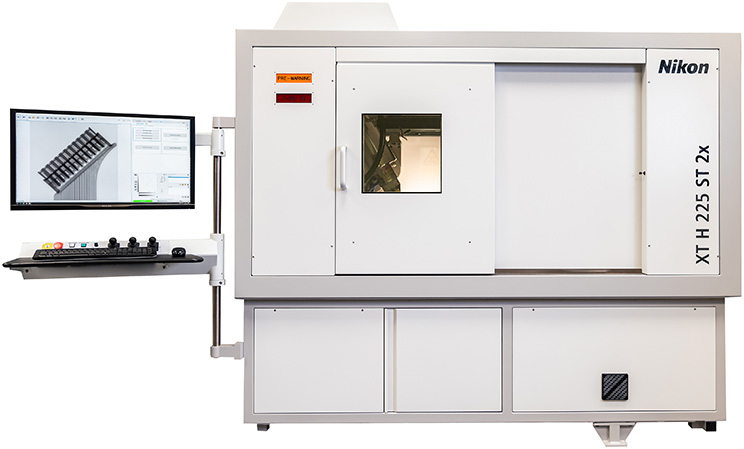

X-ray / CT Inspection Systems

IN STRATEGIC PARTNERSHIP WITH NIKON METROLOGY, WE DESIGN, BUILD AND INSTALL INDUSTRIAL 2D DIGITAL RADIOGRAPHY AND 3D COMPUTED TOMOGRAPHY SYSTEMS.

Avonix Imaging provides industrial x-ray imaging and computed tomography systems from Nikon Metrology as well as custom solutions of its own manufacture. The Nikon equipment is second to none in the industrial x-ray market with a long history in both the traditional x-ray and metrology market places.

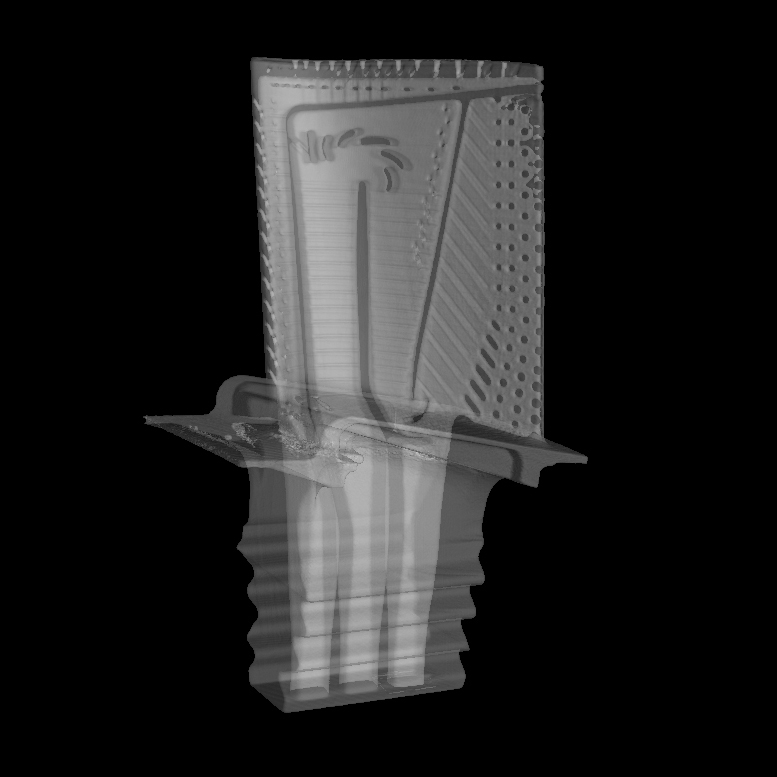

Nikon employs it’s own micro focus tube technology. Most system suppliers only offer micro focus sources up to 225kV, while more powerful sources in their offerings are mini focus. Nikon is the only company to produce micro focus sources at 160kV, 225kV, 320kV and 450kV. The focal spot size of the micro focus sources is orders of magnitude smaller compared to mini focus sources, which results in superior resolution and accuracy.

SUPERIOR RESOLUTION, ACCURACY, AND DESIGN FEATURES MAKE NIKON/AVONIX SYSTEMS THE MOST VERSATILE X-RAY IMAGING SOLUTION AVAILABLE TODAY.

SCROLL DOWN TO LEARN MORE ABOUT KEY FEATURES OF THE NIKON/AVONIX SYSTEMS:

Key Feature

225kV Microfocus Rotating Target

4X FASTER THAN THE COMPETITION.

The proprietary Nikon Liquid Cooled Rotating Target efficiently dissipates heat, allowing for significantly increased flux while retaining focal spot size. This results in scan times 3-5x faster than competition at equal resolution.

Key Feature

450kV Microfocus

Bending the laws of physics with exclusive heat dissipation technology.

Scan large and/or high density products at higher resolution than natively possible on competing systems. The liquid cooled rotating target allows the focal spot to retain a microfocus size, even at maximum energy.

Key Feature

Helical CT

NEED TO SCAN SOMETHING TALLER THAN THE NATIVE SCANNING ENVELOPE?

Helical CT allows users to scan objects taller than the scanning envelope by using a Helical acquisition. Additionally, users can use a single Helical CT acquisition to scan certain objects at much higher resolution by increasing geometric magnification.

Key Feature

Pixel Push

NEED TO DOUBLE YOUR RESOLUTION?

Pixel Push nearly doubles the spatial resolution of a detector by performing four scans with precision detector repositioning between each scan. Software then interpolates the data into a single volume for ultra-high-resolution inspection.

Key Feature

CLDA

BETTER SIGNAL. LESS SCATTER.

The advantage of a Curved LDA is the angle of incidence of the x-ray photons and the detector scintillator is optimized—resulting in better signal, less scatter and ultimately better contrast!

Key Feature

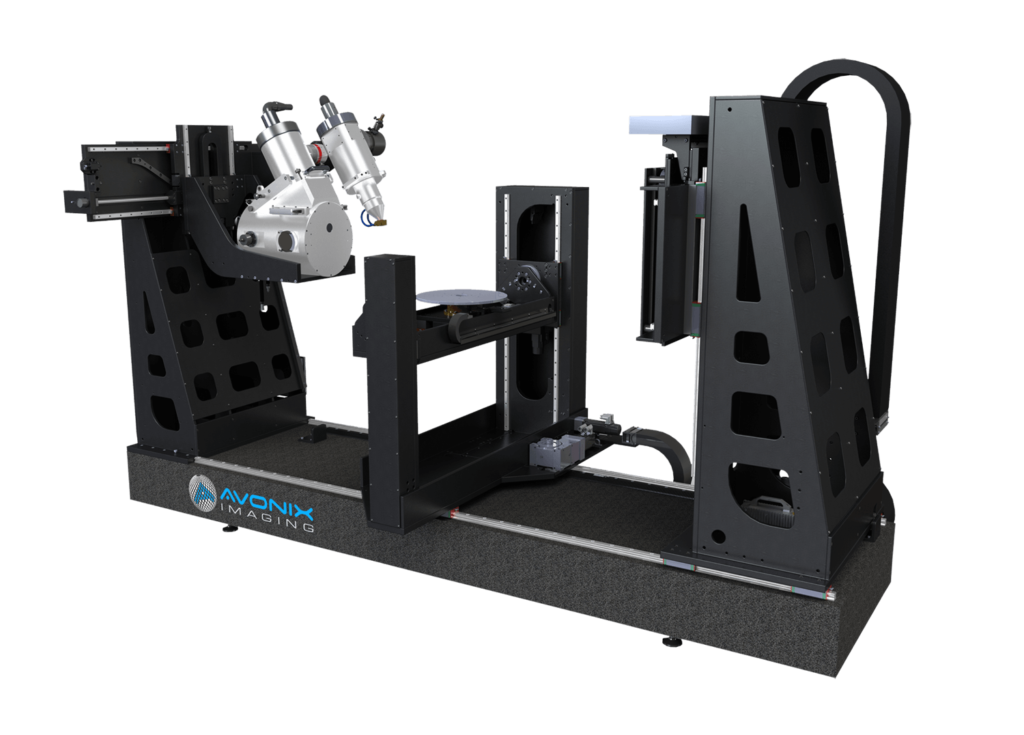

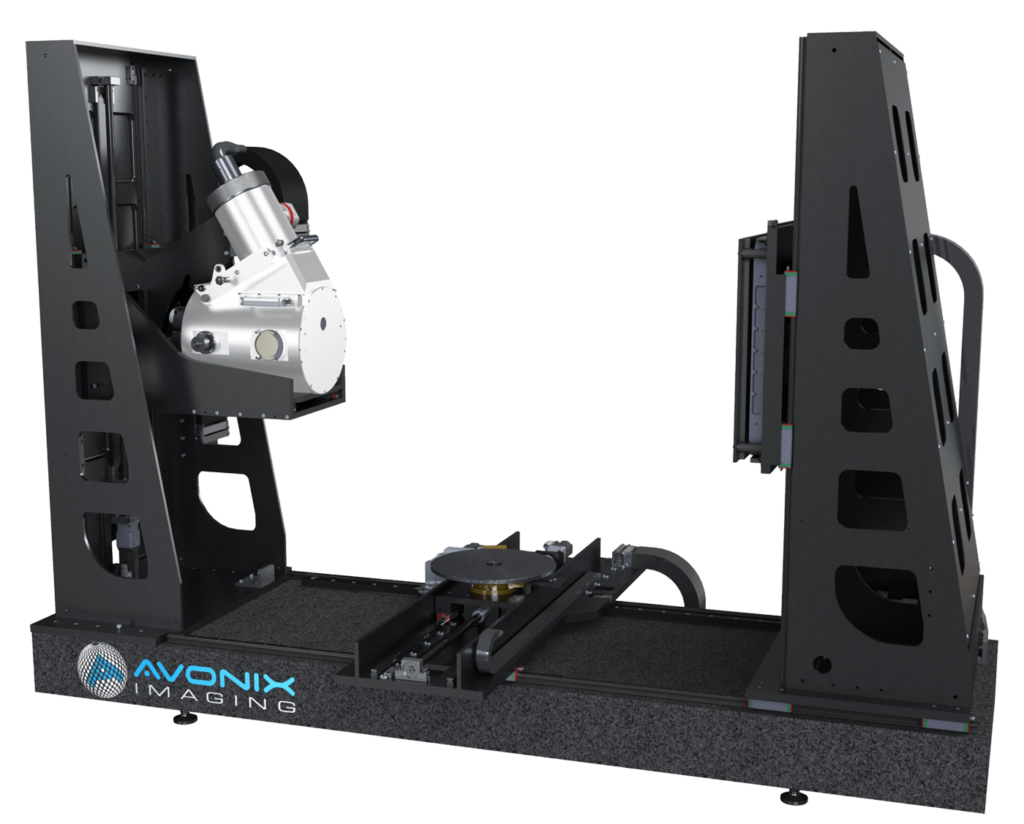

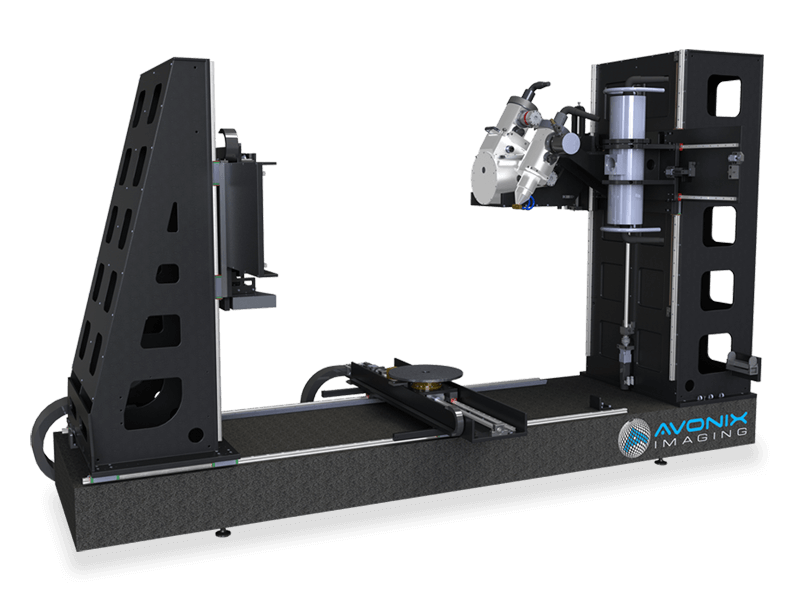

MULTI-TUBE, MULTI-DETECTOR SUPPORT

OPTIMUM HARDWARE FOR YOUR SPECIFIC APPLICATIONS

Do you need to inspect a wide range of product sizes and densities? You no longer have to purchase multiple systems; we can simply integrate multiple tubes and detectors into a single cabinet. Giving you the versatility of multiple systems in one efficient, cost-effective solution.

* Not all Features Available on Every System

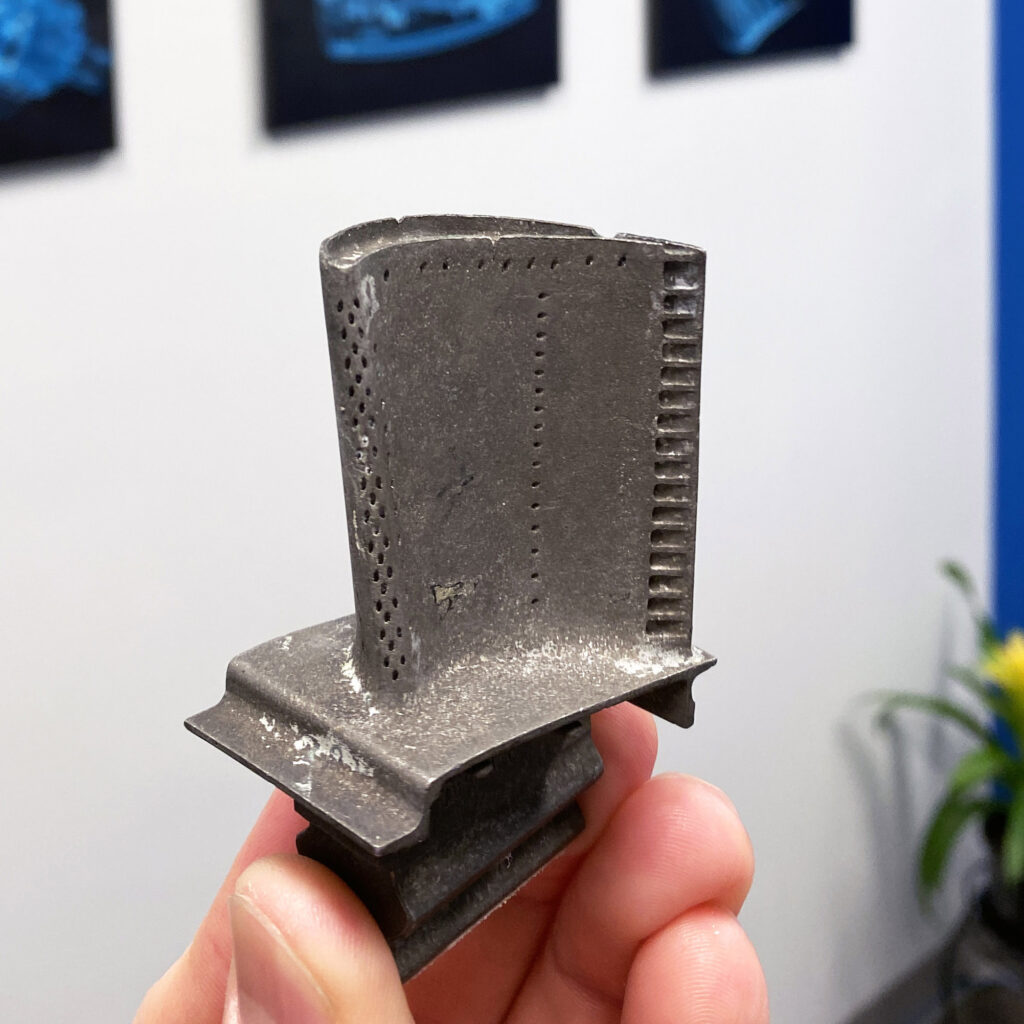

REAL-TIME X-RAY INSPECTION EQUIPMENT & CT SCANNERS

Our systems are designed to provide greater precision and performance, so you improve productivity and keep costs down. Regardless of the size of your company or the timeline of the project, we can help you streamline inspection, without sacrificing quality imaging.

WANT US TO SCAN YOUR PARTS FOR YOU?

Contact us today to discuss our Industrial X-ray Inspection Services! We'll discuss your needs, provide you with a proposed scope and estimate, so you can solve your challenge quickly!