Imaging Equipment, Products and Services

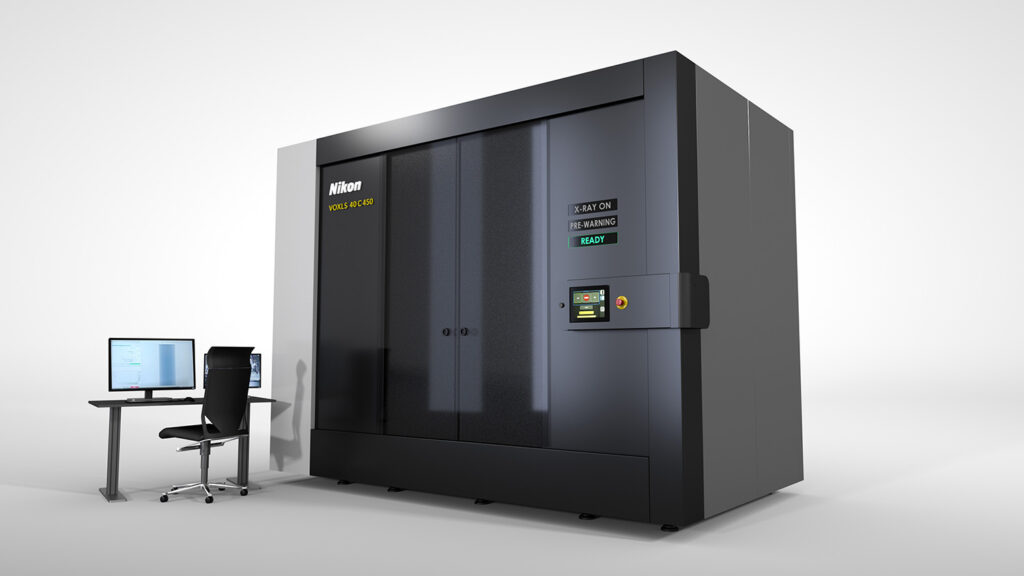

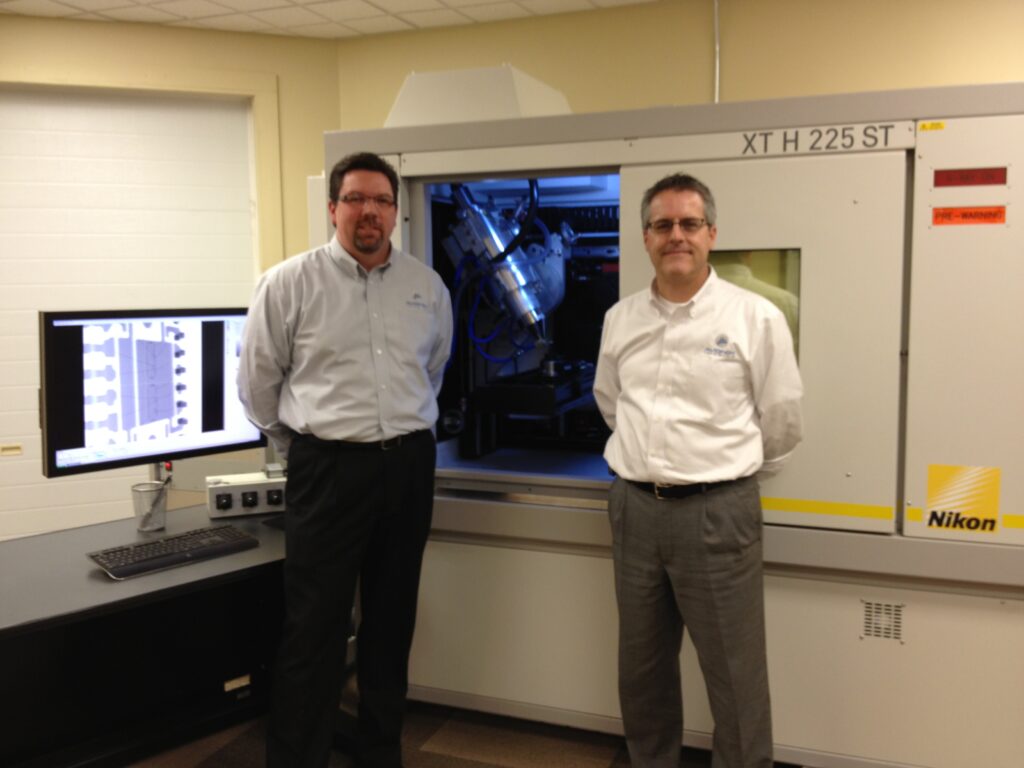

Nikon’s New Metrology Grade CT and X-Ray Machine

April 27, 2023

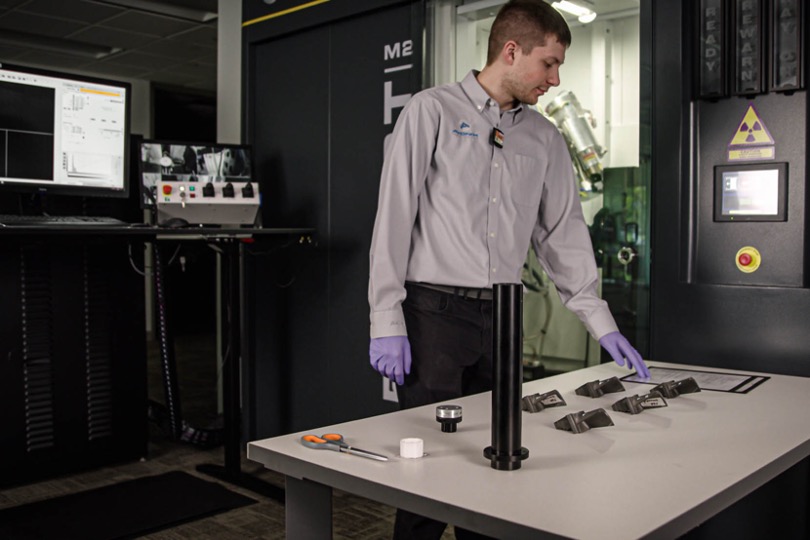

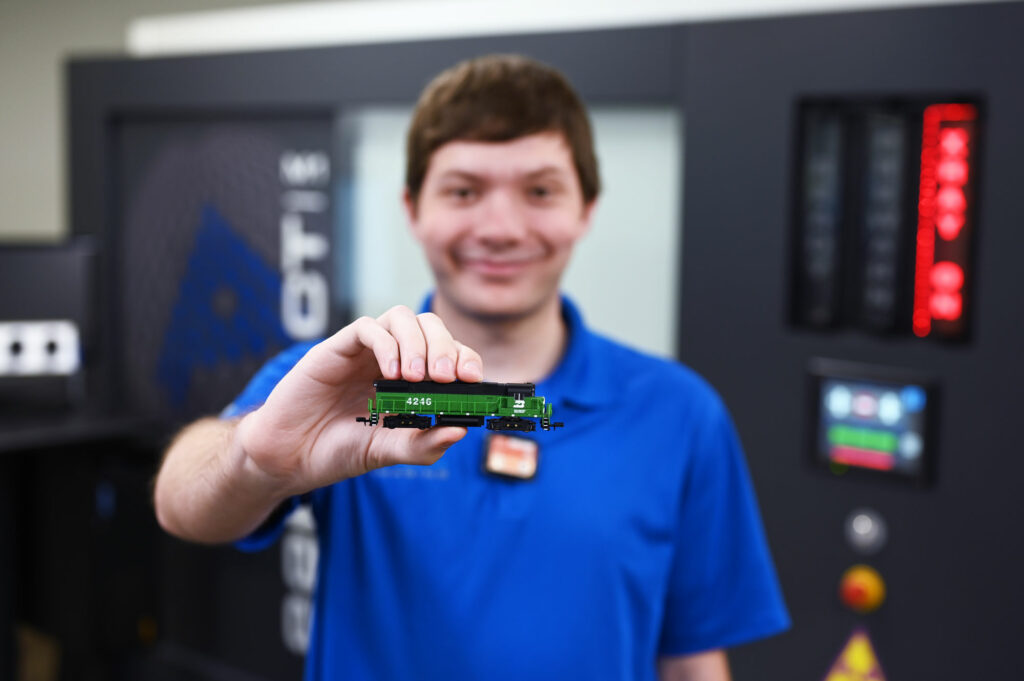

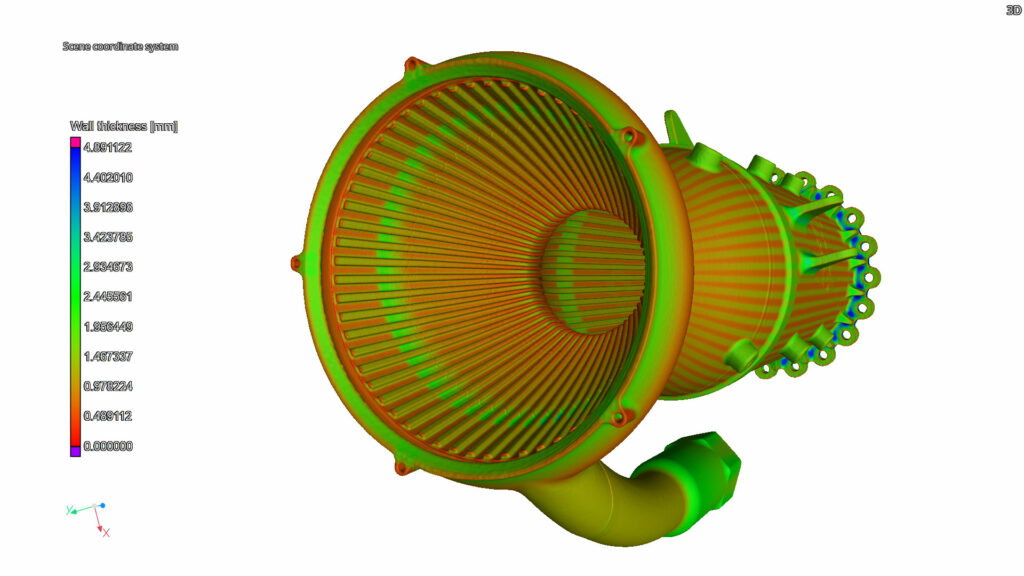

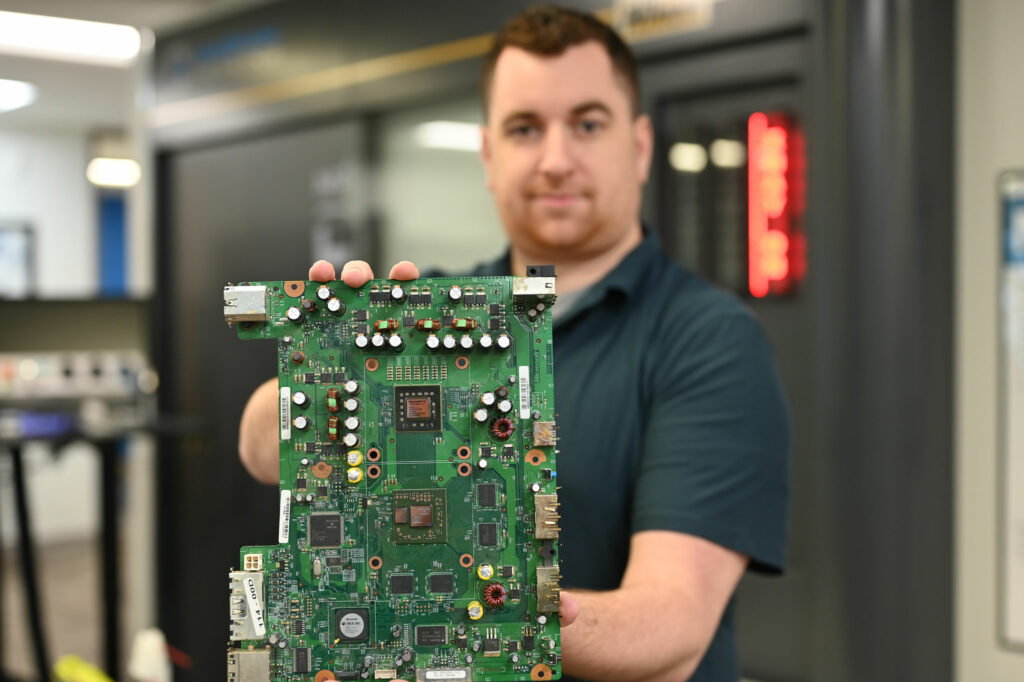

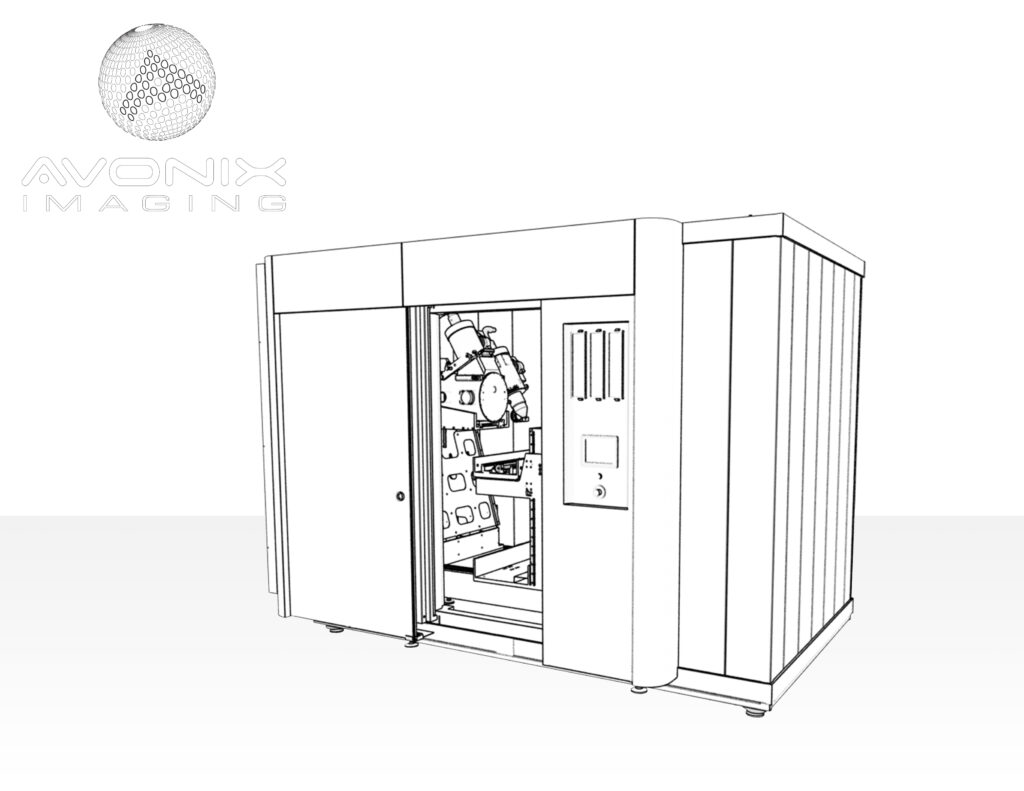

The first of an innovative range of high-performance X-ray CT (computed tomography) systems offering enhanced levels of precision, resolution and scan speed has been introduced by the Industrial Metrology Business…